Quality Control

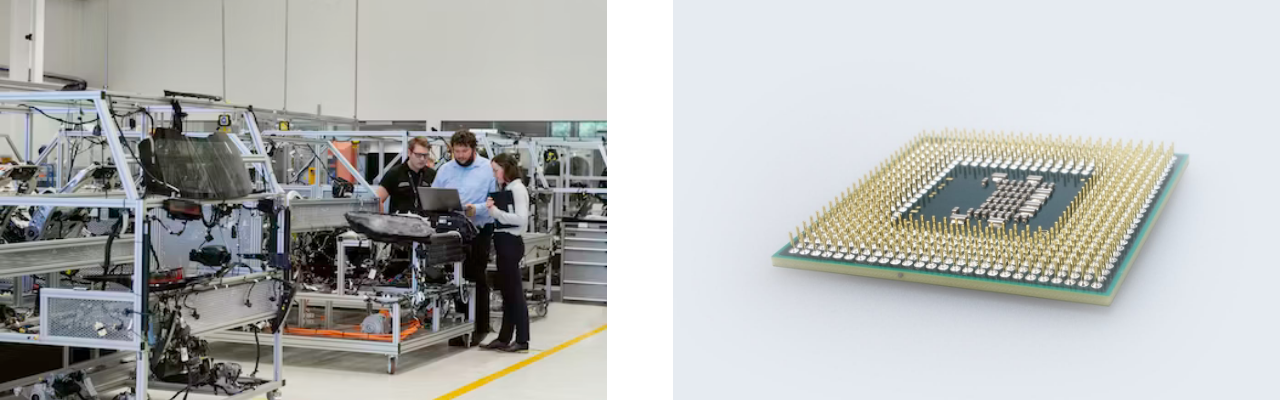

Quality control process

First Level inspection:Basic inspection

Check the label,and confirm the part number,manufacturer,datecode,quantity,ROHS and so on.

Second Level inspection:Quality Visual Inspection

According to the actual situation, decide whether to conduct part or all of the second level testing.

Check item. Verify the first stage checking results, Use high power microscope to verify whether components are qualified, Security check,Dimensional inspection. Electrical performance test to verify the circuitvalue of the capacitor. Acetone test, Take pictures and record in the database.

Third level Inspection:1st Components Test Lab/White Horse Laboratories

We cooperate with professional testing institutions for higher-level testing according to customers needs.

1st Components Test lab has a long engineering experience in electronic parts screening, qualification, and in-house test fixtures allowing us to provide the best components testing in a timely manner. 1st Components perform counterfeit part analysis on all types of electrical, electronic, and electromechanical components.

White Horse Laboratories was founded in 2004 to combat the global rise of counterfeit electronic components at the source. They are professional and Recognized in the industry.

-

Tel

15989830030 -

Wechat